Welcome to the official website of Juhua!

Stairway

Welcome to the official website of Juhua!

The aluminium grating has grown from what was an option to mild steel products catering to different environment requirements, to a product that offers a distinctive and versatile design element now featured on a number of leading edge projects. It provides access to a building while being integrated into the overall design of the building.

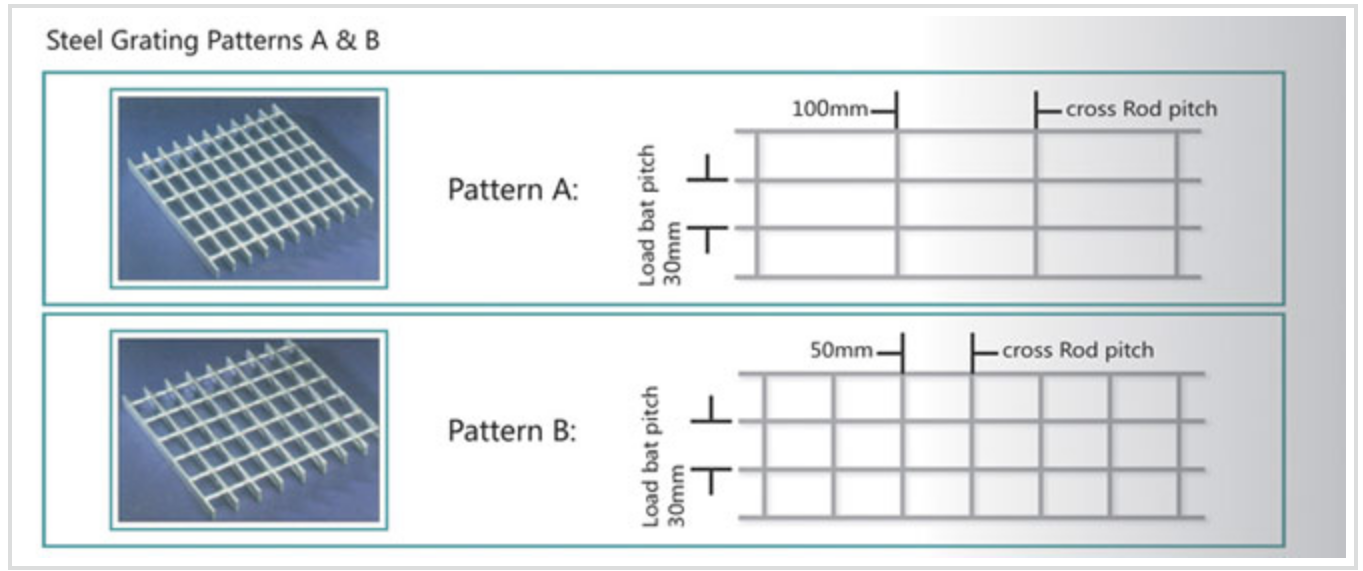

These patterns of grating conform to the AS 1657 Code for Fixed Platforms, Walkways, Stairway and Ladders. It is the product most specified and used throughout all sections of industry. This type of grating with its 30mm load bar centres has the greatest resistance to surface impact. It is used extensively in Power Stations, Refineries, Sewerage Treatment Plants, Grain Silos, Chemical Plants and as trafficable drain grates and stair treads. In its serrated form these patterns of grating are used in wet, greasy areas especially by the oil industry on offshore production platforms. Because of the number of twisted rods in the B pattern, serrations are not as effective.

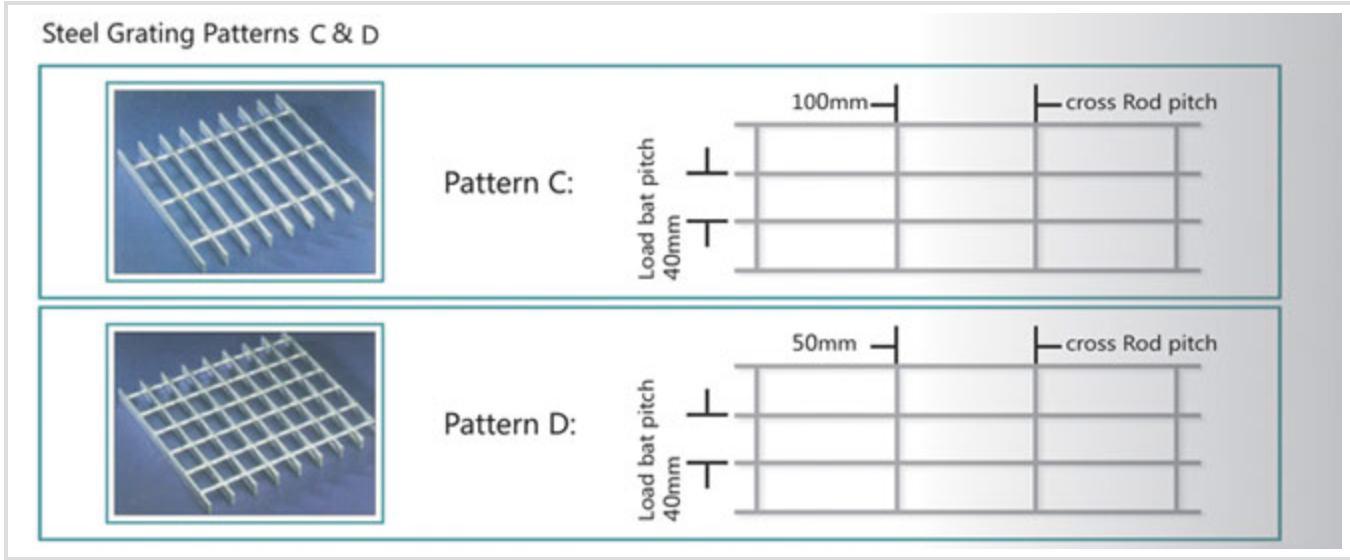

| Patterns C & D Omical than the A & B Pattern.They conform to the requirements of AS 1657. This product is ideal in areas which do not have to withstand high impacts or heavy loading.These patterns of grating are lighter and more econ |

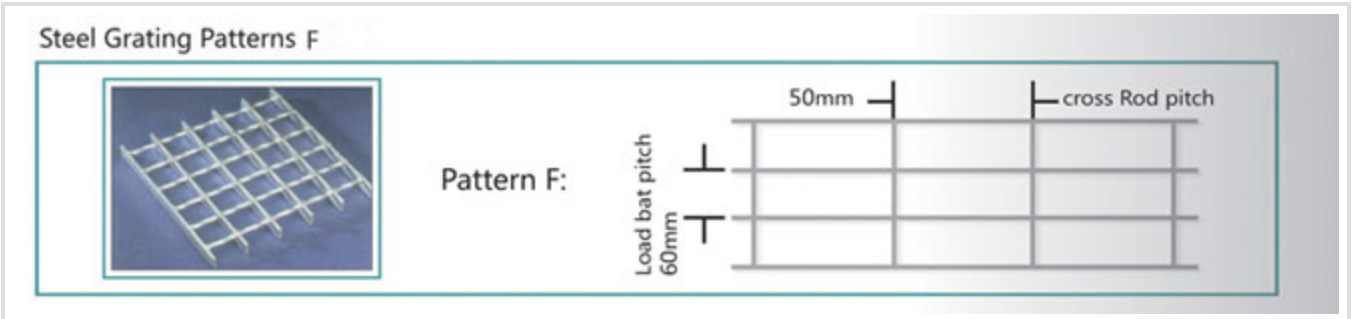

Pattern F

This grating has been specifically developed for the mining industry where spillage of material onto floors is a problem. The large square openings (nominally 60 x 50) allow most materials to fall through the grating, thus keeping the walking surface clear and safe. This product is frequently specified for conveyor walkways and floors in crusher buildings, process plants and transfer stations.

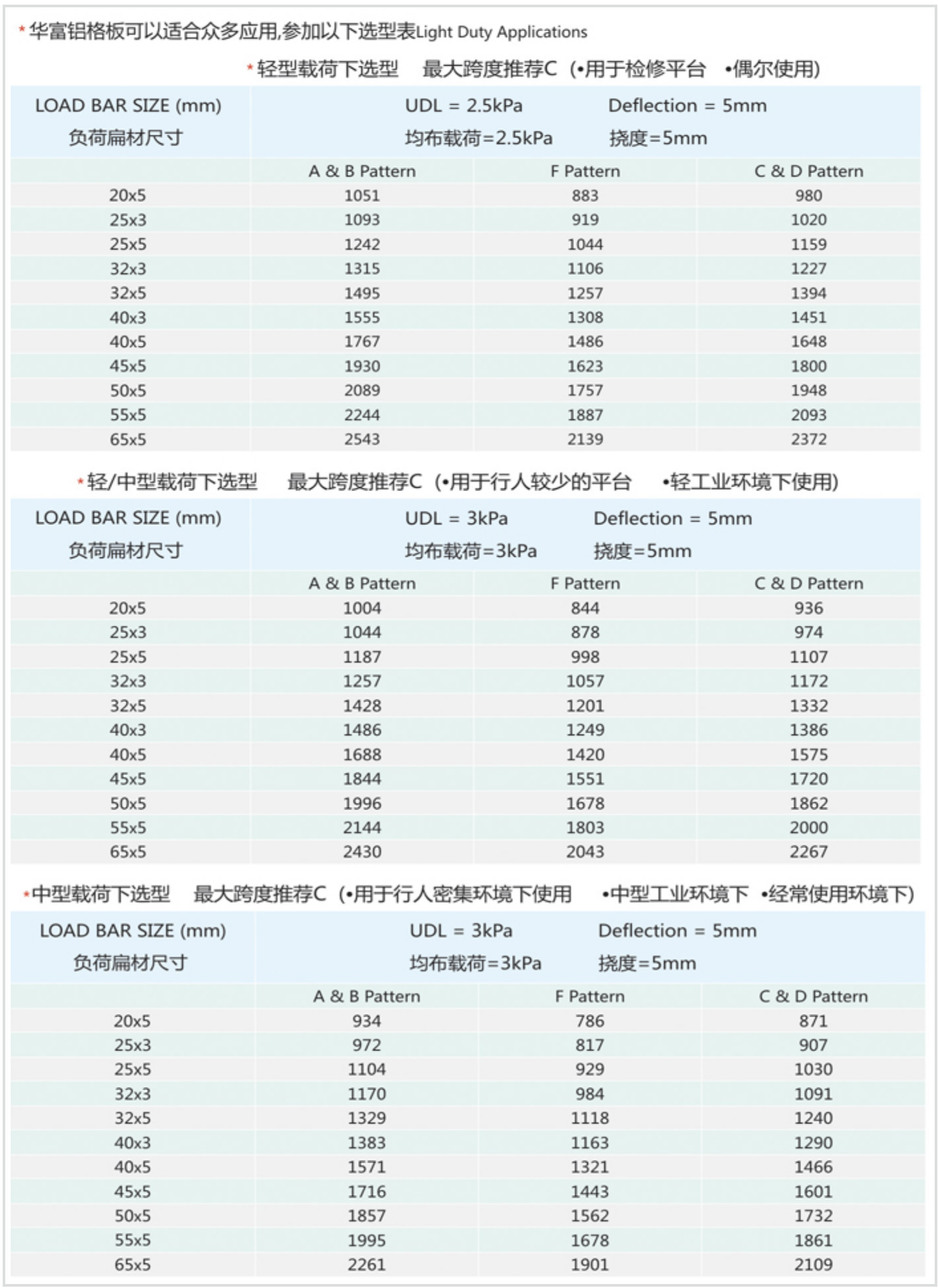

The aluminium grating is ideally suited to many applications. See below for more details and specifications.

Safety

| The slip resistance of the flooring and walkway product needs to be considered. Standard grating comparies plain square edge flat bars. To increase slip resistance the following points should be considered on sloping walkways. Although not mandated by AS 1657 the use of 10 x 10mm square bar cleats or abrasive strips can be used for additional security. ISO 14122.1 recommends cleats between 10° and 20°. Serrated grating can be specified. Stainless steel and any bars 20mm deep will not be serrated. In addition both steel and aluminium grating can improve their slip resistance by setting the direction of walking over the floor parallel to the loadbars. In steel grating there is better slip resistance in patterns with 100mm cross rod centres. i.e. Patterns A and C. |

| P | Plain |

| S | Serrated |

| G | Grit |

| R | Raised |

| F | Flattened |

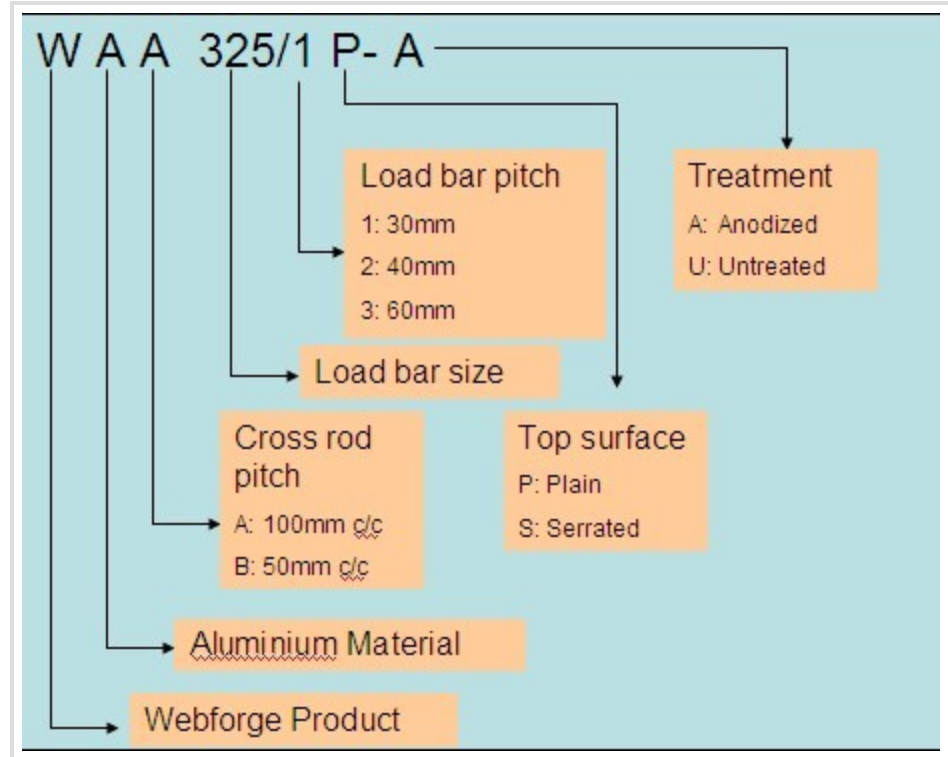

Treatment/ColourA Anodised P Painted PC Powder Coated M Mill Finish