Welcome to the official website of Juhua!

No more

Welcome to the official website of Juhua!

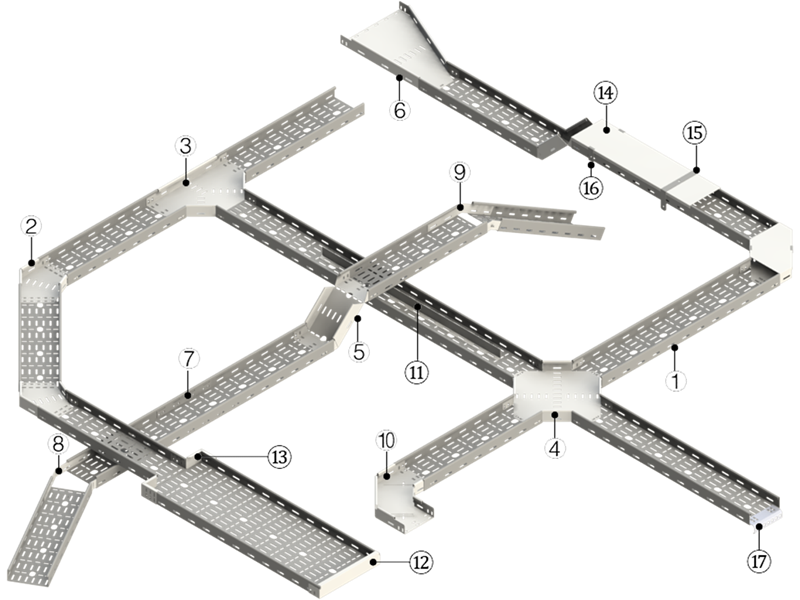

HDT steel cable tray, for heavy duty job, comes in standard height of 50 and 100mm.

The HDT Cable Tray System has a return flange on the sides and is designed with no sharp edges. The cable tray system features slot patterns allowing for optimal and efficient positioning of equipment and

easy access for cable ties and other fixings. Available in 50 and 100 mm heights, with other heights available on request.

| Material | Mild steel/SS316L/Pre-gal steel |

| Finish | HDG/Pickling passivation/Electroplate/Powdercoating |

| Certification | UL/CE/GOST-R/ABS/CSA/SGS/BV/DNV |

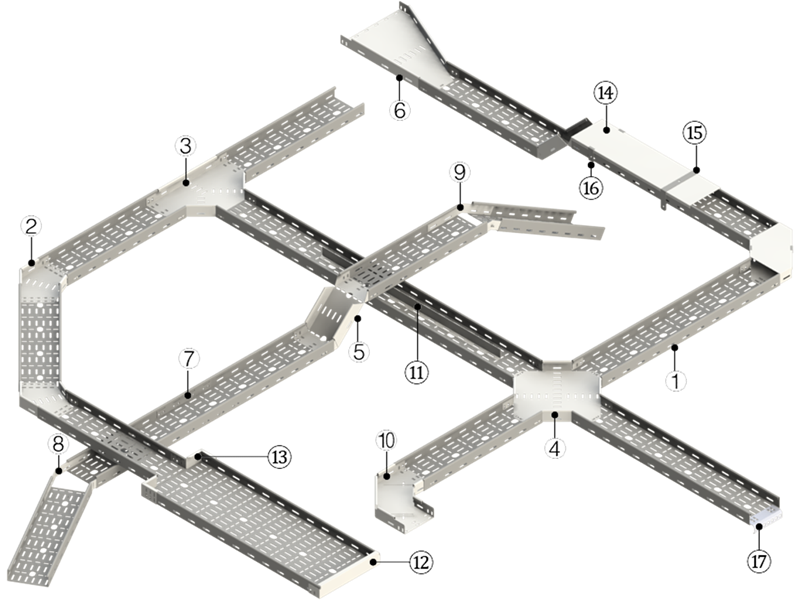

| Width | 50mm/75mm/100mm/150mm/200mm/300mm/400mm/500mm/600mm |

| Height | 50mm/100mm |

| Length | 3000mm |

Different tray heights to give more choice for loading space availability. Return flange for increased load capability. HDT cable tray comes in standard heights of 50 and 100 mm. Other heights are available on request.

Different tray widths to give more choice for loading space availability. HDT cable tray comes in standard widths of 50, 100, 150, 200, 300, 400, 500 and 600 mm. Other widths are available on request.

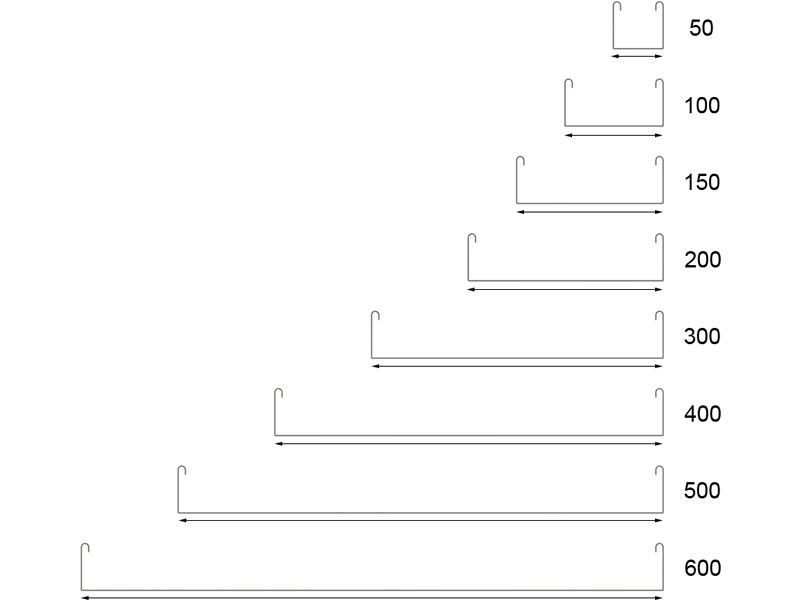

Integrated connection design saves time and effort to install, requires no extra connecting splice plate to save costs.

Related recommendations